Engineering Your Recycling Line

Advanced laboratory and industrial pilot line for material analysis and process optimization.

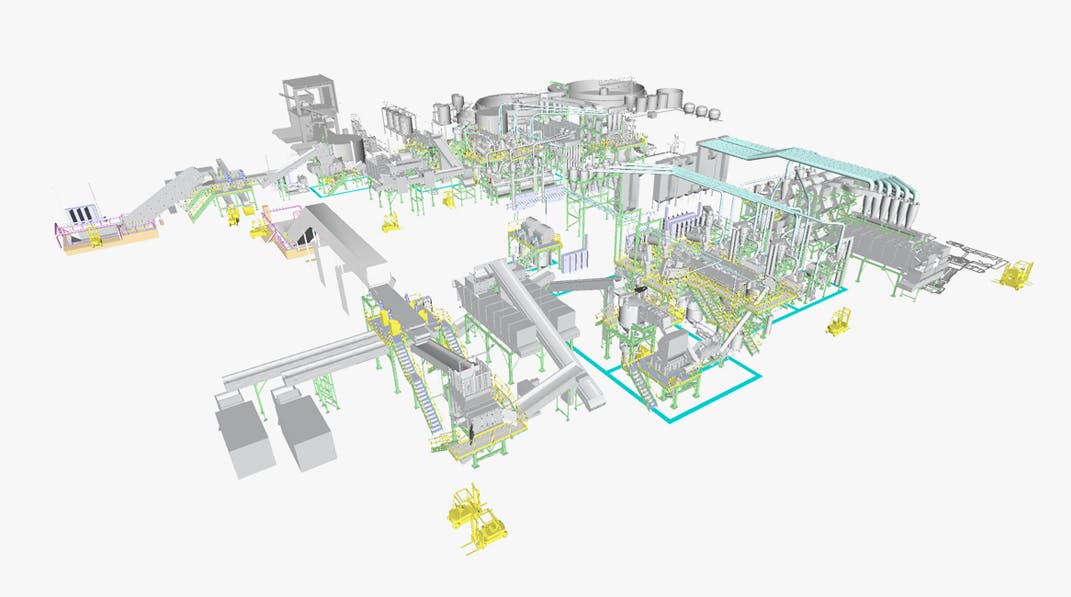

Complete plant and site design with laser scanning. Up-grade and revamping of existing lines.

Integration of ancillary equipment and wastewatertreatment plant.

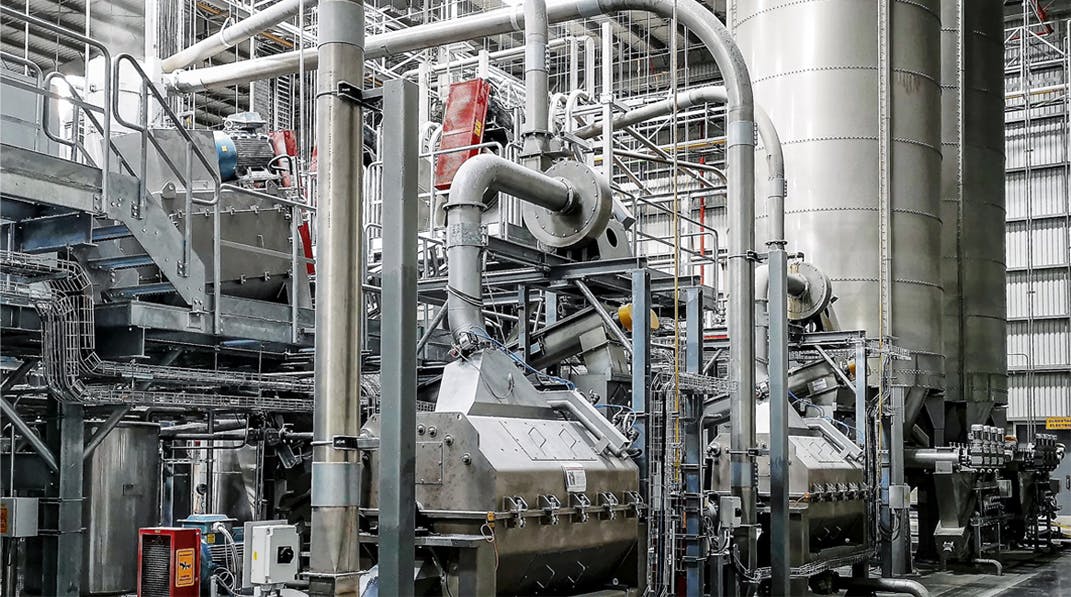

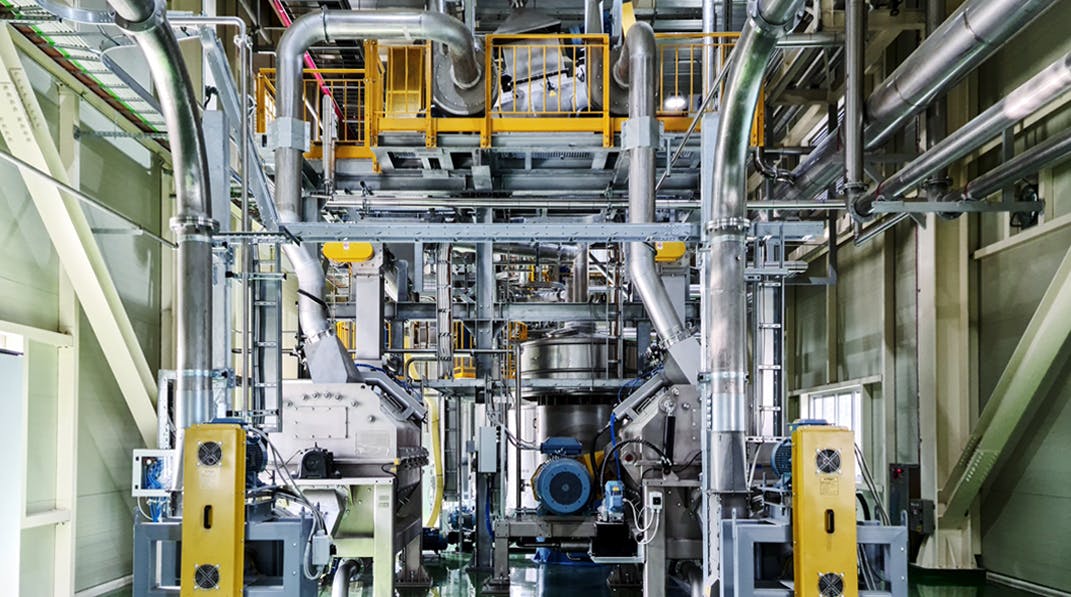

In-house machinesmanufacturing, complete pre-assembly and interface validation before shipment.

Supervision of installation, quick start-up and achievement of design capacity. Qualified technical personnel for customertraining.

Problem solving with remote support and ready-to-go assistanceteam.

Preventive maintenance and spare part programs.

Customerlong-term assistance in company management and everydayproduction.

Continuous research and development to improve flakes/fluff quality for plastic upcycling.

Open to new challenges for circular economy and sustainability with reduction in consumption of water, electricity and chemicals.

PET BOTTLES TO BOTTLES

SOREMA recycling systems transformpost-consumer PET bottles (curbside selective or deposit) into high quality recycled flakes(rPET). Typical applications are: bottles including food-grade, sheets, BOPET, fabrics, strappings and fibers.

PE/PP FILMS

SOREMA recycling systems for PE/PP films postconsumer, post-industrial or agricultural sources allow to recyclefluff ashigh-quality granules to be reused in cast, stretch, blown film extrusion lines and other upcycling applications.

HDPE/PP RIGID CONTAINERS

SOREMA recycling systems transformHDPE/PP post-consumer bottles and containers into high quality recycled flakes.

Typical applications of the flakes are: bottles including food-grade, sheets and other extruded, injected or blow-molded items.

rPET FROM TRAYS

SOREMA recycling systems transform post-consumer PET trays into high quality recycled flakes that respect the specification to be reused in thermoforms process or fibers.

DE-INKING

SOREMA deinking systems are based on modules where cured inks are removed from plastics substrate to allow the recycling and reuse of printed packaging into the original production process.

FIBER & BIG-BAGS

SOREMA recycling systems allow the decontamination of PP, PA & PET fibers, woven and non-woven fabrics, ropes and nets into flakes or granules that can be used back into the manufacturing process.

PULPER WASTE

SOREMA module, developed in cooperation with leading European paper mills, has been designed to recover fiber from pulperwaste with a high controlled friction system.

COMPLETE SOLUTIONS

To support you, Sorema provides ideal solutions and takes care of raw material handling and integration of reliable third parties equipment like bottles/flakes automatic sorting, metal separation, waste compactors, extrusion& regradation systems and, last but not least, complete wastewater treatment plants.